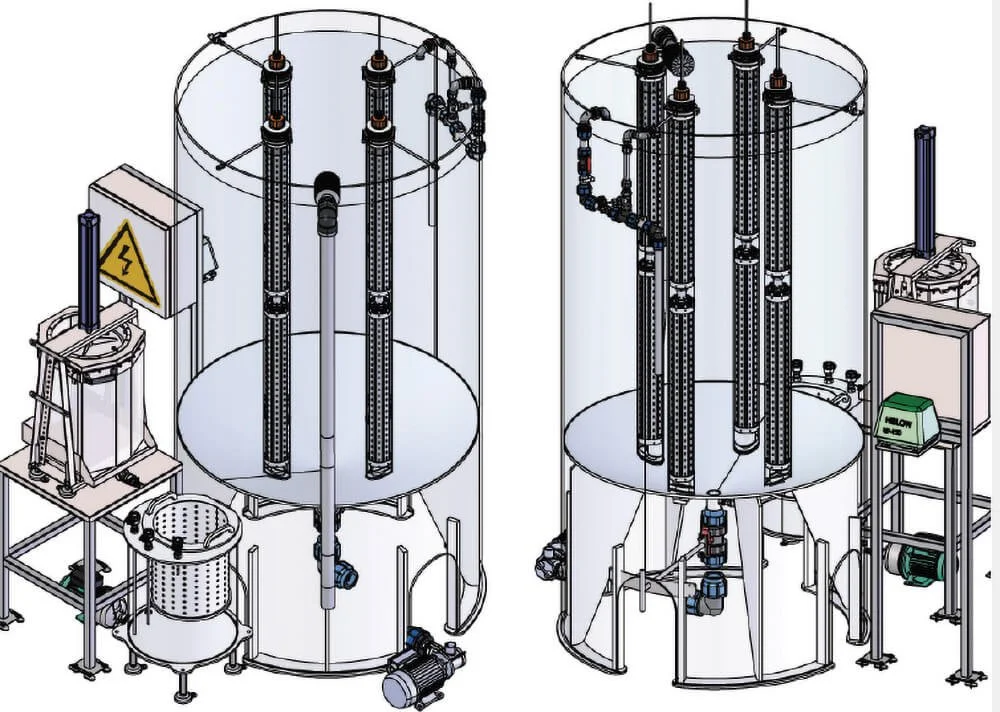

Laboratory Setup

Data-Driven Insights to Optimize Seaweed Cultivation Before Scaling

The Laboratory Setup is designed for controlled seaweed cultivation validating hypotheses at small scale. It is ideal for universities, biotech companies, and small-scale producers conducting strain selection or optimizing growth conditions before scaling up.

Description

This modular system enables precise control over key growth parameters and is characterized by:

12 bioreactors, each with a 4-liter capacity (total: 48 liters)

Adjustable water flow control for optimized nutrient and CO2 supply and continuous filtration, with optional direct cooling or heating

Adjustable air flow control ensuring optimal gas exchange with easy adjustments

User-friendly design for high-precision data collection, minimal human error, and standardized, time efficient processes

Optional sensors & IoT integration to monitor parameters such as temperature, pH, flow, salinity, and even real-time biomass growth

Relevant supplementary options, including a unique pressing unit, starter kits, and cleaning technology

With its plug-and-play design, the system is easy to install, operate, and maintain with minimal time investment and low skill requirements.

Your Benefits

This setup provides precise, reproducible conditions, ensuring reliable research outcomes while reducing costs and risks associated with large-scale investments. Aligned with Pure Algae’s core technology, it supports data-driven feasibility studies for commercial scaling. Its rapid implementation enables quick results with minimal effort.

Ideal for:

✓ Strain selection & comparison

✓ Cultivation parameter testing

✓ Growth optimization

Best suited for:

Research

Seaweed Grow-out

Biotech

Why choose it:

Designed specifically for seaweed cultivation

Plug-and-play setup – fast and intuitive installation

Standardized design for replicable, high-quality data

Supporting different research stages

For early-stage screening or experiments, many teams choose between the Laboratory Setup (flow) and our Laboratory Batch Setup.

The Incubator Unit serves as a single PBR, our lowest cost system, and it is effective for inducing sporulation in e.g. Ulva. and could be considered as the pre-stage to experimentation with either of the Laboratory Setups.

As projects progress toward larger-scale development, clients often scale into the VALUEFARM Container for industrial scale production and finally the VALUEFARM Towers for cultivation at the largest scale possible.

“We were impressed by how quickly the Laboratory Setup was set up and running – it truly is plug-and-play.”

Laboratory Setup at Aarhus University

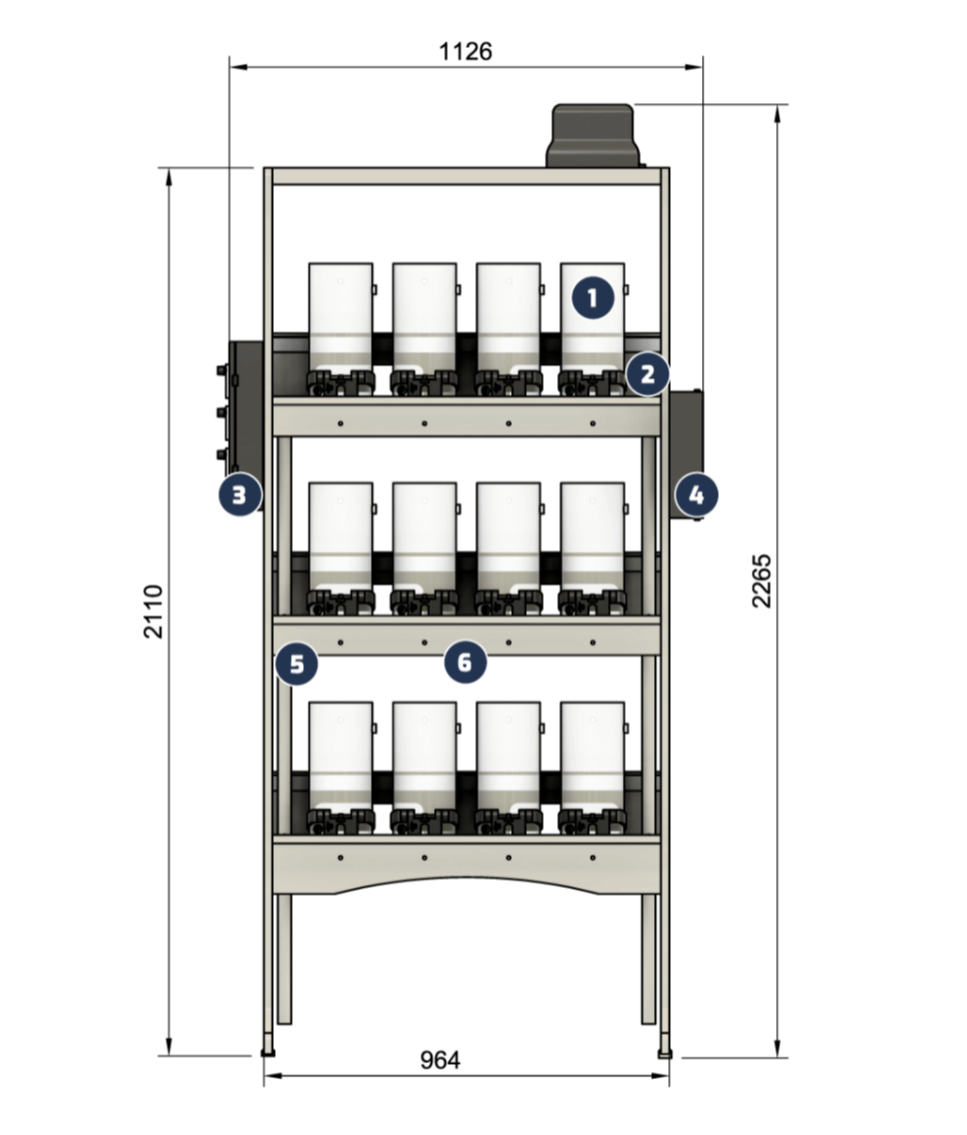

Specifications

[1 ] Bioreactors

[2] Easy harvesting module

[3] Air flow control

[4] Water flow control

[5] Light control

[6] Unique shelf systems with drains

[7] Pumps, filtration, and sterilization

[8] Buffer tank

[9] Optional cooling and/or sensors

Technical Specifications

Power Supply: Universal power supply 220 V, 50 Hz

Max Power Usage: 300W (750W with cooling)

System size: 2105 x 964 x 450 mm (H x W x D)

Bioreactors: H: 300 mm, Ø: 150 mm,

Functional volume: 4 L

Buffer tank: 330 x 820 x 415 mm (H x W x D),

Functional Volume: 90 L.

Net Weight: 100 kg (250 kg with water)

The Laboratory Setup in use

Our Laboratory Setup is used for hands-on testing of cultivation parameters and nutrient content targeting.

It enables practical evaluation of biological behaviour under controlled conditions.

The setup supports iterative testing, data collection and refinement of operational choices.

Insights gained here may be used to back design and growth decisions before moving on to production scale.

Other Products